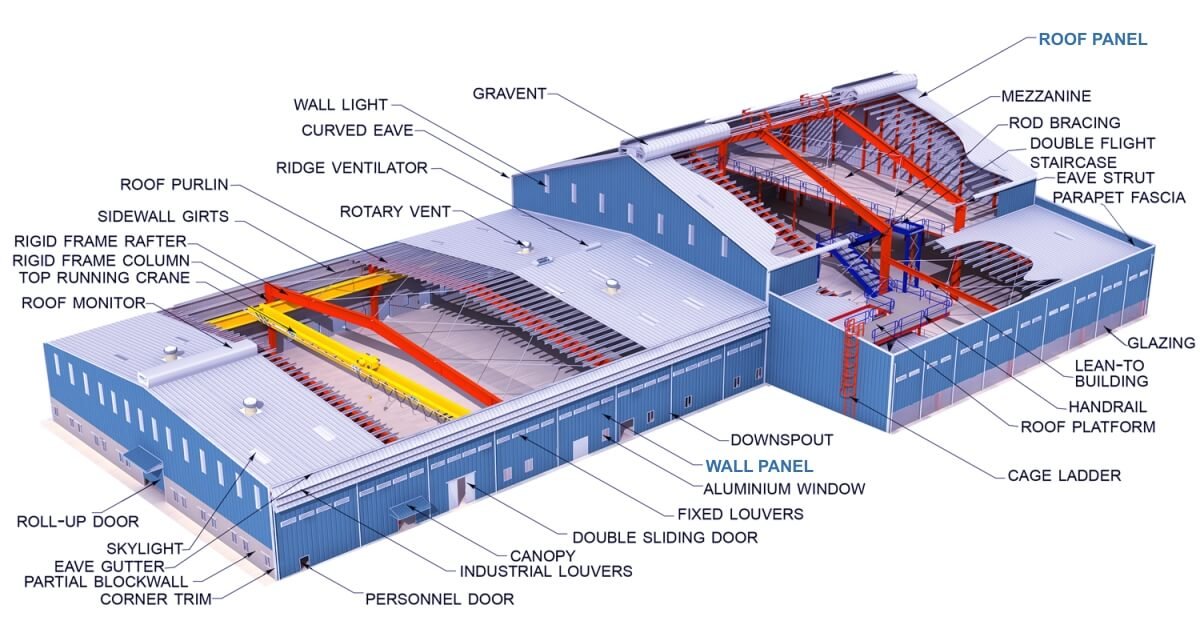

Insulated Panel Manufacturer You Can Trust

Insulated Panel Manufacturer CLASSIFICATION & PARAMETERS

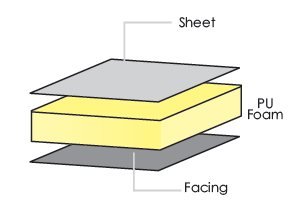

Facing

thickness

Thickness Available:

30mm 40mm 50mm 60mm 80mm100mm120mm

FEATURES OF Insulated Panel Manufacturer

Fast To Construct

Our Insulated Panel Manufacturer Sheets are custom built from factory itself hence they require very less installation time on site. These insulated panel manufacturer sandwich panels are also very easy to install thus saving time

Insulation – Heat Proof

Our thermal insulation material is made of high quality Rigid Polyurethane Foam (PUF), considered to be one of the most efficient and high performance insulation material. High quality standard of Insulated Panel Manufacturer enables high savings in heating and cooling cost.

Strong Load Bearing

Insulated Panel Manufacturer can withstand compressive load of over 1 ton per square feet. On long spans it can take significant load (live as well as dead). Insulated Panel Manufacturer Insulated Panel Manufacturer requires very less or no support structure due to its self-strength.

Edge Protect Technology

“EDGE PROTECT TECHNOLOGY is a proprietary process that closes the thickness side edges of painted metal sheets with a weatherproof coat. This protects the edges from rust and corrosion, extending the lifespan of the Insulated Panel Manufacturer.

“

Weather Shield For Ultra Long Life

Insulated Panel Manufacturer feature a coating, which is an extra thick layer of paint that provides superior protection against the elements. The Weather Shield coating is also UV resistant, which means that it will not fade or crack in the sun. This makes Insulated Panel Manufacturer Roof panels

Technical Specification Of Insulated Panel

| Panel thickness available | 30mm, 40mm, 50mm, 60mm, 80mm, 100mm, 120mm |

| Panel total width | 1070mm |

| Panel effective width | 1000mm |

| Panel length available | 1000mm-15000mm |

| Density | 40± 2kg/m3 |

| Thermal conductivity | 0.024-0.03 W/m |

| Temperature range | -40+800C |

| CFC / HFC | Free from CFC / HFC |

| Type of foam | B1, B2, B3, PIR |

| Heat transfer co-efficient | -0.022W/M2*k |

| Pressure | 0.10Mpa |

| Top coat | 5 + 15 micron |

| Back coat | 5 + 5 micron |

| 500h (ECCA TB) | 100 h (ASTM D 2247) |

CLASSIFICATION BASED ON THICKNESS OF PANEL

50mm puf panel

50mm panels are the most ideal thickness of puf sheet. They offer the best mix of insulation, strength and cost. These are a good choice for all constructions like roof top room, hospital floor, school classrooms, roof top restaurant construction, penthouse etc.

30mm puf panel

30mm panels are the most economical type of panel. They are a good choice as an alternative for metal roofing sheets.

65mm puf panel

65mm panels are a good choice for applications where high levels of insulation are required and where extreme cold or heat is a concern, such as refrigerated warehouses and cold storage facilities

40mm puf panels

40mm panels are thicker than 30mm panels and offer more insulation and strength. They are a good choice for applications where budget is is important factor, such as servant classrooms, staff quarters, temporary offices etc.

105mm puf panel

105mm panels are the thickest type of panel available. They offer the highest levels of insulation and are a good choice for applications where extreme cold or heat is a major concern, such as sub-zero refrigerator, cryogenic chambers and blast freezers.

All things you need to know

"Everything About Insulated Panel Manufacturer: Types, Price, Features And More "

Insulated Panel

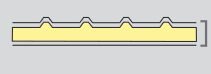

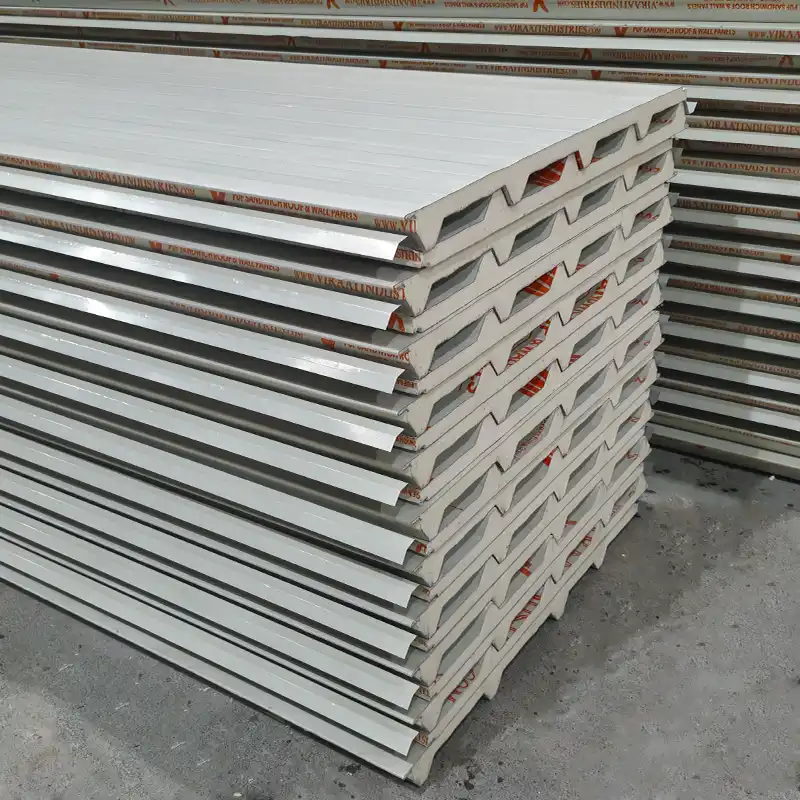

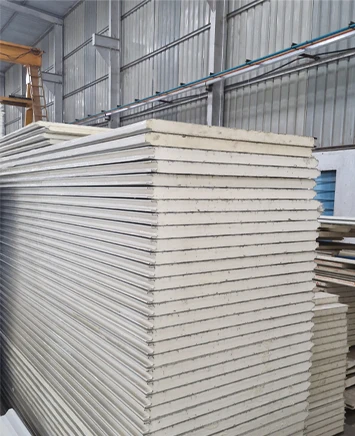

Made from top-quality material, PUF roof sheets are constructed to withstand the harshest weather conditions. The variety of colors and finishes allows seamless integration into the design of your office or home. They are ideal for warehouses PEB industries small rooms, and farmhouses, these roof sheets improve the aesthetics of your home while ensuring unbeatable durability. Polyutherene Foam as the core is injected between 2 sheets with Highly Sophisticated Computer Controlled Foaming Machine. The Panel is Manufactured in a Continuous Line Production Method & compromises of 5 corrugation, 250mm Pitch with exterior baby ribs for extra strength.

Polyurethane Foam Density of 40+- 2kg/m3 with Guard Film Protection on all exposed surface & confirms to IS12346.

Weather Endurance

Withstand harsh climates effortlessly.

Energy Efficiency

Maintain optimal temperatures, saving on energy bills.

Versatile Application

Ideal for diverse spaces, from warehouses to residential homes.

Get a personalized quote for your project and explore exceptional solutions crafted just for you!

Leading Insulated Panel

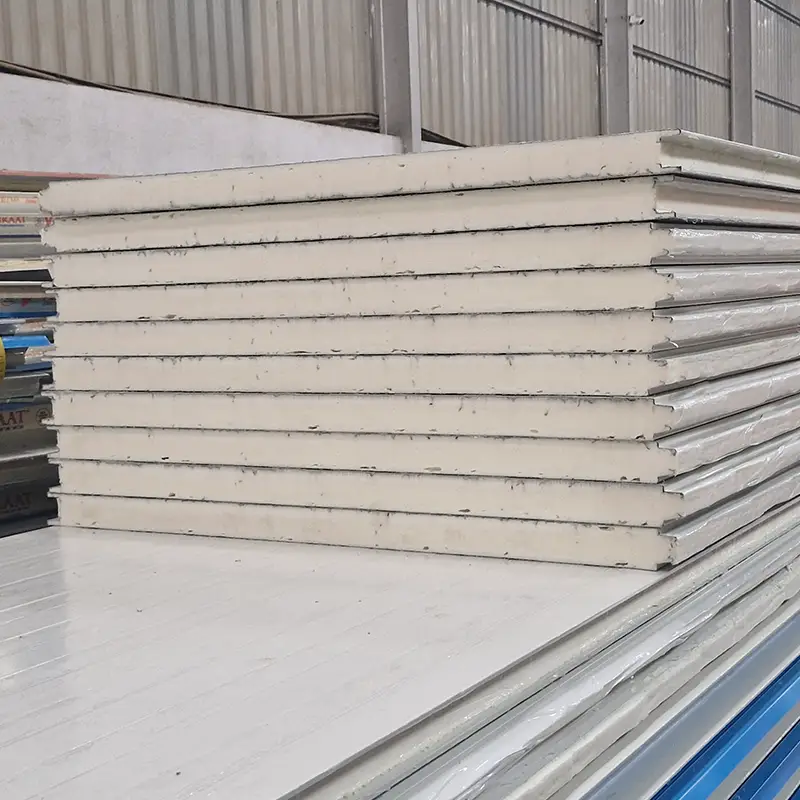

The wall panels are a affordable alternative to traditional walls and partitions. With a price that is significantly lower than the alternatives of aluminum or masonry These prefabricated, custom-designed walls can be used for both commercial and residential applications. The light high-performance polyurethane foam base which is sandwiched between tough cement board or sheet metal provides toughness, durability and a simple installation. Available in a variety of thicknesses as well as colors and also we are introducing new Wood Finish Texture color option The panel walls transform exterior walls as well as partitions for interior spaces.

Cost-Effective

40% to 50% cheaper than conventional walls/partitions.

Easy Installation

Lightweight design for effortless setup.

Versatile Design

Options for various thicknesses, colors, and textures.

Receive a quote for your project and unlock tailored solutions that are second to none.

Clientele